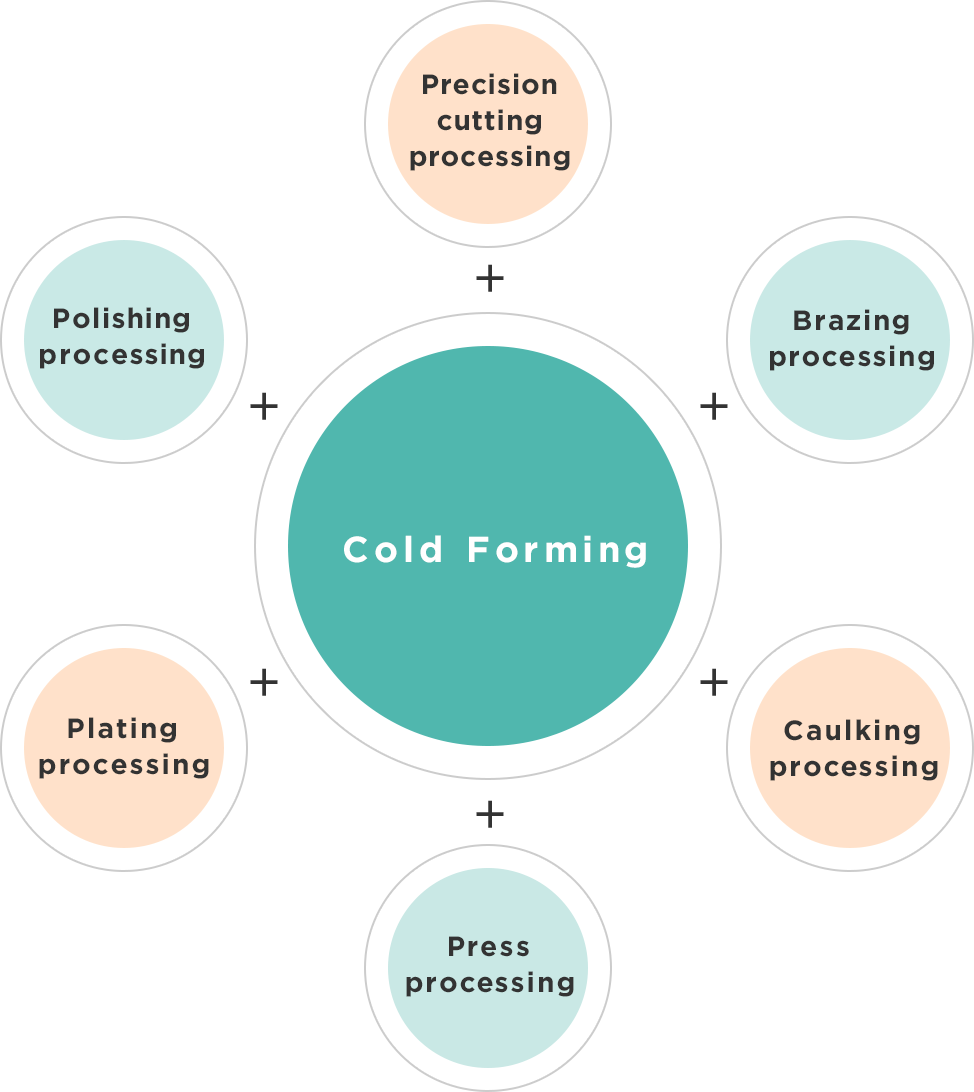

Okawa Screw Manufacturing has contributed to the manufacturing of parts in various fields such as the automobile industry, construction, home appliances, precision instruments, etc. Our technologies are based on cold forming to make it possible to realize mass production with high precision as well as high quality, even for complicated shapes which have been considered impossible in the past.

Please contact us if you have problems about metal processing, from development of new products to improvement of existing products.

We will give you propose of an optimal solution that demonstrates the triple effects of high accuracy × high efficiency × cost performance.

By utilizing our proprietary technologies and consistently supporting process design, prototyping and mass production, we can achieve reductions in process loss, lead time, cost, resource saving and so on. We will contribute to your high added value production.

It is the main molding of cold forming, which greatly deforms the material with one compression. It can process arbitrary parts such as anterior and or posterior.

It is a method of increasing the cross section while simultaneously compressing the material in the axial direction to reduce the height. It is used to process the head section of parts.

It is a method of molding with highly accurate to the final shape by one time cold forming without requiring finishing such as cutting.

It is possible to shorten delivery time and reduce cost by integrating molding with our parts formers instead of conventional welding structures.

It can be applied to various requirements such as fine holes, multiple holes, and irregular shaped holes. It is possible to achieve a significant loss in secondary processing.

It is processing to deform the material while rotating it. There are twisting processing, drawing processing, groove processing, etc.

It can be produced energizing parts of copper materials at high speed with cold forming, such as charge connector terminals for electric vehicles.

We are also developing different material processing methods such as aluminum and stainless steel.

| Available Field | Vehicle parts for automobiles and motorcycles, building related products, home appliances, environmental products, and, electronic devices, etc. |

|---|---|

| Available Materials | Iron, stainless steel, aluminum, copper, etc. |

| Production capacity | We can adapt to match your requirements from the prototype for mass production to actual mass production processing of 20 million pieces / month. |

| Production Equipment | Parts formers, bolts formers, CNC6-axis automatic lathes, 8-axis automatic lathes, brazing furnace, original image inspection machine, etc. |

Okawa Screw Manufacturing has established the R&D center in the main Mito Factory at 2017 in order to further strengthen "Manufacturing power" with the core of cold forming technology and "Training production engineering human resources" from a long-term and global perspectives. Production engineers and design workers of equipment and molds are gathered at the center. We are engaged in R&D on products and new process methods with unprecedented values.

![]()

![]()

![]()

![]()

![]()

![]()

A. We will listen and act upon your requirements. We will ask about your current processing methods and requests and, then we will propose the optimum processing method. So please feel free to contact us as a first step.

A. Besides the core technology cold forming processing, we also support precision cutting, welding (brazing) processing, automatic inspection system development and so on.

Because of our integrated production, it is also possible to combine processing methods according to lots and specifications, as well as to parallel at the same time.

We offer great merit to customers who need high quality and high precision products quickly.

A. Mass production will be from 1 million pieces per month, but we also accept consultation for small lots.

A. We can do it, however we may request to be paid for a prototype before a formal request.

A. Please contact the sales department first for visiting the factory.

A. We will ask about the packing and delivery method of your request and we will match as much as possible.

Reception time :

Weekdays 9:00 ~ 17:00 *except Saturdays / Sundays, or company holidays